INVITE - Digital Plant Showcase Center with SIMATIC PCS neo and MTP

INVITE GmbH in CHEMPARK Leverkusen operates a Digital Plant Showcase Center to test promising new digital technologies quickly and easily on a plant. The target is to build a bridge between technology scouting and implementation in production. Two advantages are combined: First, the plant represents a production process so that the transfer to the real application is minimized. Second, it has the flexibility and freedom of a pilot plant. Participants will gain first experiences and are able to access the suitability for operation in production.

The "Digital Plant" is the center of the Digital Plant Showcase Center (see Figure 1). The digital plant is a system that is designed and implemented modular. That means it consists of modules in terms of process, construction and automation. This makes the plant flexible in its structure and open to expansion. In addition, the use of standardized communication interfaces makes it easy to integrate digital technologies.

A single module implements each process step. The Digital Plant consists of five modules:

- 3 feed modules (short name: BP11, BP12 and BP13)

- 1 mixing and heating module (short name: CM14)

- 1 stirring and storing (short name: RP23)

According to a brownfield approach, the automation is partially modular. This means that two feeding modules (BP12 and BP13) are controlled using a Module Type Package (MTP). The modules BP11, CM14 and RP23 are conventionally controlled via a process control system. The newly developed control system from Siemens SIMATIC PCS neo is used as the process control system.

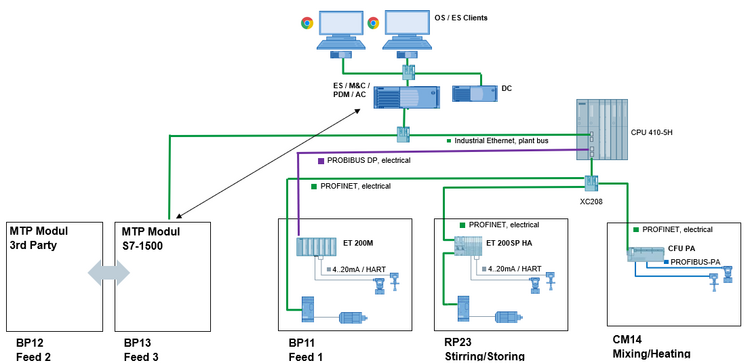

The process control configuration of SIMATIC PCS neo consists of a server for engineering and operation & monitoring, as well as two web clients. On the automation side, a CPU 410-5H with ET200SP-HA and CFU-PA with ProfiNet, as well as an ET200M with Profibus DP are used. The Sinamics G120C frequency converters are integrated with ProfiNet (see Figure 2).

The operation of Simatic PCS neo as a completely web-based system in HTML5 takes place exclusively via web browser, local software installations are completely dispensed with: The user can access all information at any time and from any location quickly and easily via protected connections. Web-based means that web technologies are used in the interaction of the server and clients. This opens up lots of new possibilities without a connection to the World Wide Web being required to operate SIMATIC PCS neo.

Based on the experience gained through commissioning, implementation of first changes and throughout the operating phase, we were able to gain a positive impression of SIMATIC PCS neo. In particular, the user-friendly web client architecture and session management, within the framework of multi-user engineering, are considered very good. Several users can work on the same project worldwide at the same time. The basis for the collaboration is a clear management of rights and roles, a secure session concept and a consistent object structure in engineering, simulation and automation. That saves time and the data storage is always consistent.

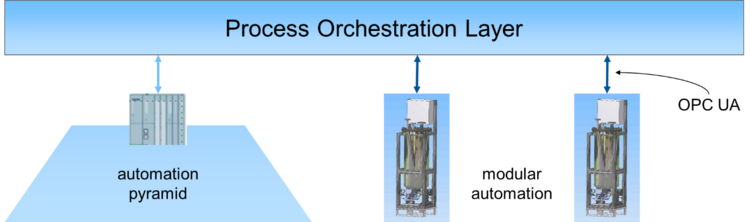

In addition to its function as a control system, the focus is also on SIMATIC PCS neo in the role of a Process Orchestration Layer (POL) (see Figure 3). The POL has the task of integrating and orchestrating modules via the Module Type Package (MTP). Specifically, the MTP modules are integrated in SIMATIC PCS neo via the OPC UA communication protocol. In this pilot, a limited MTP scope with regard to visualization and operation was initially used, in accordance with the status of the associated VDI 2658, which is currently still being worked on.

For the MTP module with SIMATIC S7-1500, the SIMATIC MTP (APL) library was used even before the release. The SIMATIC Module Type Package Library (MTP) offers blocks and faceplates based on the Advanced Process Library (APL) for modular automation of various applications.

In order to emphasize the manufacturer independence of the MTP, a module with the control technology from Festo SE & Co. KG was integrated, too. The integration of the MTP from the third-party provider was also successful. For the operator of the Digital Plant, there is no difference between classic automation, Siemens MTP or Festo MTP.

However, the real advantage of the MTP is the engineering. The Digtial Plant shows that it is possible to integrate a module or a package unit into the POL within 10 minutes. This is possible because the visualization and signal interconnection of the module are already included in the MTP. After the successful import of the MTP package file, only the OPC UA connection needs to be configured. This is how the “plug and produce” idea is implemented using the MTP. INVITE has already carried out online presentations on the digital plant with SIMATIC PCS neo and MTP with several participants from BAYER and other companies. Above all, the web-based approach and the possibility of fast integration of modules or package units using MTP was convincing, even if some functionalities, which are required for the process and pharmaceutical industry, are still in development. The development of SIMATIC PCS neo is being followed particularly with regard to the production systems where SIMATIC PCS 7 is already in use. Another focus is the migration of plants with SIMATIC PCS 7 to SIMATIC PCS neo. The common hardware platform and application architecture of the two systems is a great advantage here.

The portfolio of showcases for digitalization is being further expanded at Invite. In addition to SIMATIC PCS neo and MTP, a pilot setup on the topic of NAMUR Open Architecture (NOA) is currently on display (see full news). Focus of this showcase is to establish a connection between HART-enabled field devices and cloud applications in order to establish an IT/OT integration for brownfield.